Tel:86-0750-6228802

Fax:86-0750-6228277

Mobile Phone:+8617718861990

Email:yingtong@yingtongpack.com

Address:Xinsha Industry, Muzhou Town, Xinhui District, Jiangmen, Guangdong Country Region China

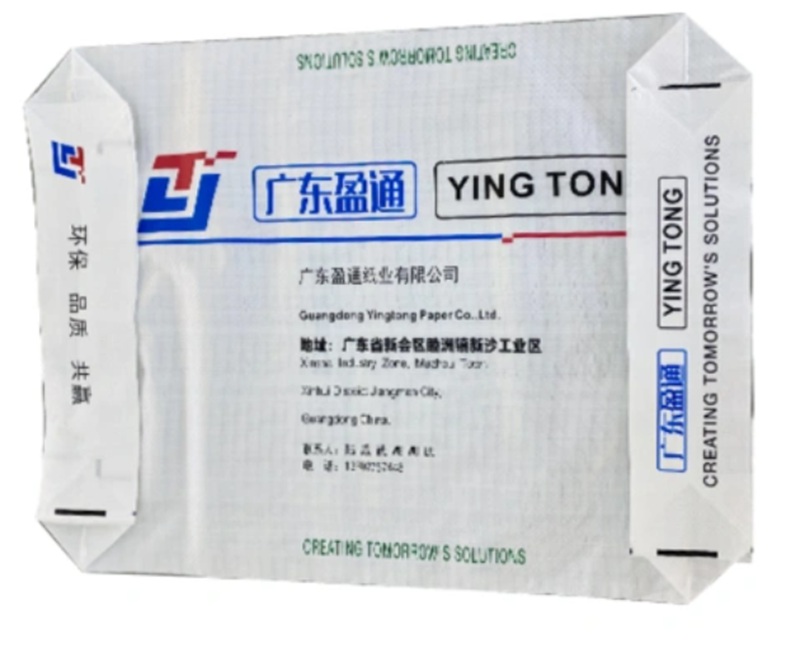

White Woven Polypropylene Sacks are white woven bags made from polypropylene (PP). This material, produced through a special weaving process, exhibits excellent flexibility and durability. Widely used in the packaging industry, it is favored for its cost-effectiveness and environmental performance. These woven bags are typically used to package various granular, powdered, or bulk items, effectively protecting the integrity of the product during transportation and storage. Their white appearance also makes them visually appealing, making them suitable for a variety of packaging needs.

Product color: 1-4 colors

Finished size: length 450-910, width 350-600, bottom width 80-180

Pattern customization: plastic woven bags can be customized according to customer requirements

Brand: OEM

Place Of Origin: China

Industry Application: Cement

Making Process: Composite Packaging Bag

Raw Materials: High Pressure Polyethylene Plastic Bag

Bag Variety: Upright Bag

Application: Chemical

Feature: Bio-Degradable

Material: PP

Shape: Square Bottom Bag

1. High Strength and Durability

Square Bottom White Woven Polypropylene Sacks are made from high-quality polypropylene (PP) using an advanced weaving process. This material offers exceptional strength and toughness, capable of withstanding significant weight and pressure. Its breaking strength reaches [X] N/cm², ensuring it resists breakage during packaging and transportation. This high strength makes it ideal for packaging heavy items such as cement and chemical raw materials, effectively protecting them from damage.

2. Environmentally Friendly and Degradable

White Woven Polypropylene Sacks are biodegradable, aligning with modern environmental protection concepts. Its primary component, polypropylene, gradually decomposes in the natural environment, minimizing long-term environmental pollution. This eco-friendliness allows them to be safely discarded or recycled after use, reducing environmental impact. Its degradation cycle is typically [X] years, significantly shorter than that of traditional plastic materials, strongly supporting sustainable development.

3. Customizable Design

White Woven Polypropylene Sacks offer a high degree of customization to meet the specific needs of individual customers. From size to color, from pattern to printing, all can be customized according to customer requirements. Finished product sizes range from 450-910 mm in length, 350-600 mm in width, and 80-180 mm in bottom width, adapting to various product packaging specifications. Furthermore, one- to four-color printing is available upon request, enhancing packaging personalization and brand recognition.

4. Versatility

Square Bottom White Woven Polypropylene Sacks are versatile and suitable for a wide range of industries and applications. Their unique square bottom design provides greater stability during stacking and transportation, effectively utilizing space. This design not only improves packaging efficiency but also reduces transportation costs. Furthermore, their excellent air permeability makes them suitable for packaging products that require ventilation, such as grain and feed, effectively preventing moisture and spoilage.

5. Affordability

White Woven Polypropylene Sacks offer high cost-effectiveness while maintaining quality. Their low raw material costs and mature production process effectively control production costs. This affordability makes it highly competitive in the market, particularly suitable for large-scale packaging needs. Its price is typically [X]% lower than similar products, providing customers with a cost-effective option.

1. Cement Packaging:

Square Bottom White Woven Polypropylene Sacks are an ideal packaging option for the cement industry. Their high strength and durability can withstand the weight of cement, ensuring it will not break during transportation. Their square bottom design provides greater stability when stacked, effectively utilizing space and reducing transportation costs. Furthermore, their excellent sealing properties prevent moisture from entering the cement, preserving its quality.

2. Chemical Raw Material Packaging:

White Woven Polypropylene Sacks are suitable for packaging chemical raw materials. Their polypropylene material offers excellent chemical stability and is resistant to most chemicals. Customizable designs can be tailored to the characteristics of different chemical raw materials, ensuring safe and reliable packaging. Their excellent air permeability also prevents the leakage of volatile chemical raw materials, protecting the environment and personnel.

3. Food Packaging:

White Woven Polypropylene Sacks can be used for packaging food products such as grain and feed. Their excellent air permeability prevents moisture and spoilage, maintaining their freshness. Their eco-friendly and biodegradable properties meet food industry safety standards, ensuring food safety during the packaging process. Furthermore, their customizable designs can be tailored to the type and size of food, meeting the needs of diverse customers.

4. Agricultural Packaging:

White Woven Polypropylene Sacks are also widely used in the agricultural sector. Their high strength and durability can withstand the weight of agricultural products, ensuring they are not damaged during transportation. Their excellent air permeability prevents moisture and mold, preserving their quality. Furthermore, their customizable designs can be tailored to the characteristics of different agricultural products, meeting the diverse needs of agricultural production.

5. Building Material Packaging:

Square Bottom White Woven Polypropylene Sacks are suitable for packaging building materials such as tiles and stone. Their high strength and durability can withstand the weight of building materials, ensuring they do not break during transportation. Its square bottom design makes it more stable when stacked, effectively utilizing space and reducing transportation costs. In addition, its customizable design can be adjusted to the specifications of different building materials, meeting the packaging needs of the building materials industry.

The bags are made from high-quality woven materials, ensuring strength and durability for heavy-duty use.

The square bottom design allows the bags to stand upright, facilitating easy filling, stacking, and storage, which enhances efficiency in handling and transportation.

The valve pocket feature provides a quick and secure closure, minimizing spillage and ensuring that the contents remain intact during transit.

Yes, the bags can be customized to meet specific branding and size requirements, offering a versatile solution for different businesses.

These bags are ideal for packaging a wide range of materials, including cement, fertilizers, grains, bulk food items, chemicals, and more.

Yes, the bags are designed to withstand rough handling and various environmental conditions, making them suitable for industrial and commercial use.

Yes, the bags are made from recyclable materials, offering an environmentally friendly packaging solution.

Industries such as construction, agriculture, food, chemicals, retail, manufacturing, mining, pharmaceuticals, textiles, and recycling commonly use these bags.

WhatsApp:

WhatsApp: Phone:

Phone: Contact Now

Contact Now