Tel:86-0750-6228802

Fax:86-0750-6228277

Mobile Phone:+8617718861990

Email:yingtong@yingtongpack.com

Address:Xinsha Industry, Muzhou Town, Xinhui District, Jiangmen, Guangdong Country Region China

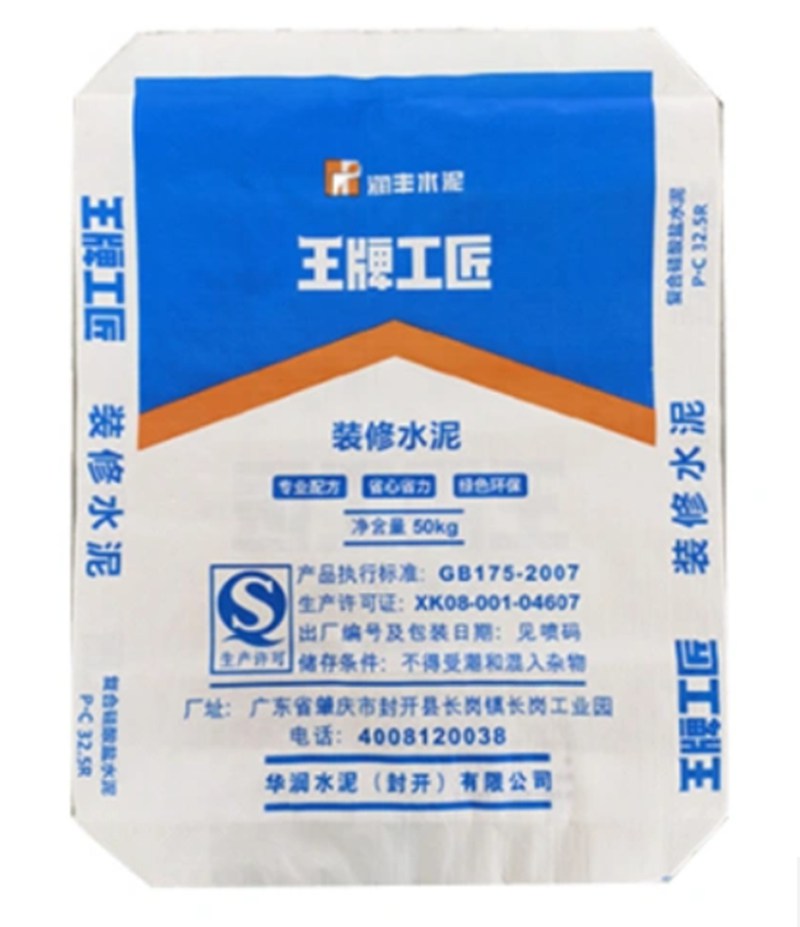

valve packaging bag is a specialized type of packaging solution. It is designed to provide a secure and efficient way to package various products. This type of bag features a valve mechanism which allows for easy filling and sealing of the contents. The structure of the valve packaging bag is carefully crafted to ensure the integrity and protection of the packaged items during transportation and storage. It is widely recognized in the packaging industry for its reliability and functionality.

Product color: 1-4 colors

Finished size: length 450-910, width 350-600, bottom width 80-180

Pattern customization: plastic woven bags can be customized according to customer requirements

Brand: OEM

Place Of Origin: China

Industry Application: Cement

Making Process: Composite Packaging Bag

Raw Materials: High Pressure Polyethylene Plastic Bag

Bag Variety: Upright Bag

Application: Chemical

Feature: Bio-Degradable

Material: PP

Shape: Square Bottom Bag

A Range of Color Options:

Composite Valve Packaging Bag offers a range of color options to meet different needs. It can be produced in 1 to 4 colors. This allows customers to choose the color that best suits their branding or product requirements. For example, a company may prefer a specific color to make their packaging more visually appealing and recognizable in the market. The ability to customize the color adds value to the packaging solution.

Customizable Size:

The finished size of Composite Valve Packaging Bag is highly customizable. The length can range from 450 to 910 millimeters, the width from 350 to 600 millimeters, and the bottom width from 80 to 180 millimeters. This flexibility in size ensures that the bag can accommodate a variety of product volumes. Whether it is used for packaging cement or other materials, the right size can be selected to optimize the packaging process and ensure the contents are well protected.

Pattern Customization:

One of the standout features of Composite Valve Packaging Bag is its pattern customization. Plastic woven bags, which are a type of valve packaging bag, can be customized according to customer requirements. This means that customers can have their own unique designs and logos printed on the bags. This not only enhances the visual appeal but also serves as a form of branding and marketing. It allows businesses to create a distinctive packaging solution that stands out in the market.

OEM Branding:

Composite Valve Packaging Bag supports OEM branding. This means that customers can have their own brand name and logo printed on the packaging bags. It is an effective way for companies to promote their brand and build brand recognition. By having their brand clearly displayed on the packaging, it helps to create a strong brand image and increases customer loyalty.

Made in China:

The origin of Composite Valve Packaging Bag is China. China is known for its advanced manufacturing capabilities and high-quality production standards in the packaging industry. This ensures that the bags are produced with precision and meet the required quality standards. The manufacturing facilities in China have the expertise and technology to produce high-quality valve packaging bags that are reliable and durable.

Manufacturing Process:

The making process of Composite Valve Packaging Bag involves composite packaging techniques. This process combines different materials to create a strong and durable packaging bag. The composite structure enhances the bag's strength and resistance to wear and tear. It ensures that the bag can effectively protect the contents during transportation and storage. The manufacturing process is carried out with strict quality control to measures ensure the final product meets the industry standards.

Material Quality:

Composite Valve Packaging Bag is made from high-quality raw materials. The main material used is high-pressure polyethylene plastic bag. This material is known for its durability and resistance to moisture. It provides a reliable barrier to protect the contents the of bag. The use of high-quality materials ensures that the bag can withstand the rigors of transportation and storage, making it a trustworthy packaging solution.

Cement Packaging:

Composite Valve Packaging Bag is widely used in the cement industry. It provides an excellent packaging solution for cement due to its ability to protect the cement from moisture and other environmental factors. The bag's robust structure ensures that the cement remains intact during transportation and storage. This helps to maintain the quality of the cement and ensures that it can be used effectively for construction purposes.

Chemical Packaging:

Composite Valve Packaging Bag is also suitable for packaging chemicals. The bag's material and structure make it resistant to chemical reactions. This ensures that the chemicals remain safe and stable inside the bag. The valve mechanism allows for easy filling and sealing, making it a convenient packaging option for chemical products. It helps to prevent any leakage or contamination of the chemicals during transportation and storage.

Food Packaging:

Composite Valve Packaging Bag can be used for food packaging as well. The bag's material is food-grade and safe for contact with food products. It provides a barrier to protect the food from external factors such as moisture, air, and contaminants. The customizable size and pattern options allow for a tailored packaging solution to meet the specific requirements of different food products. It helps to maintain the freshness and quality of the food during transportation and storage.

Agricultural Packaging:

In the agricultural industry, Composite Valve Packaging Bag is used for packaging various agricultural products. It can be used to package seeds, fertilizers, and other agricultural materials. The bag's durability and protection features ensure that the agricultural products remain in good condition. The valve packaging bag helps to prevent any damage or contamination of the products during transportation and storage, ensuring that they can be used effectively in agricultural activities.

Building Materials Packaging:

Composite Valve Packaging Bag is a reliable packaging option for building materials. It can be used to package items such as sand, gravel, and other construction materials. The bag's strength and durability make it capable of withstanding the weight and characteristics of these materials. The valve mechanism allows for easy filling and sealing, making it a convenient packaging solution for the building materials industry. It helps to protect the materials from moisture and other external factors, ensuring their quality is maintained.

Industrial Packaging:

Composite Valve Packaging Bag is also used in various industrial applications. It can be used to package a wide range of industrial products such as powders, granules, and other bulk materials. The bag's composite structure and material provide a strong and reliable packaging solution. The customizable features allow for a tailored packaging solution to meet the specific requirements of different industrial products. It helps to ensure the safe and efficient transportation and storage of these products.

WhatsApp:

WhatsApp: Phone:

Phone: Contact Now

Contact Now