Tel:86-0750-6228802

Fax:86-0750-6228277

Mobile Phone:+8617718861990

Email:yingtong@yingtongpack.com

Address:Xinsha Industry, Muzhou Town, Xinhui District, Jiangmen, Guangdong Country Region China

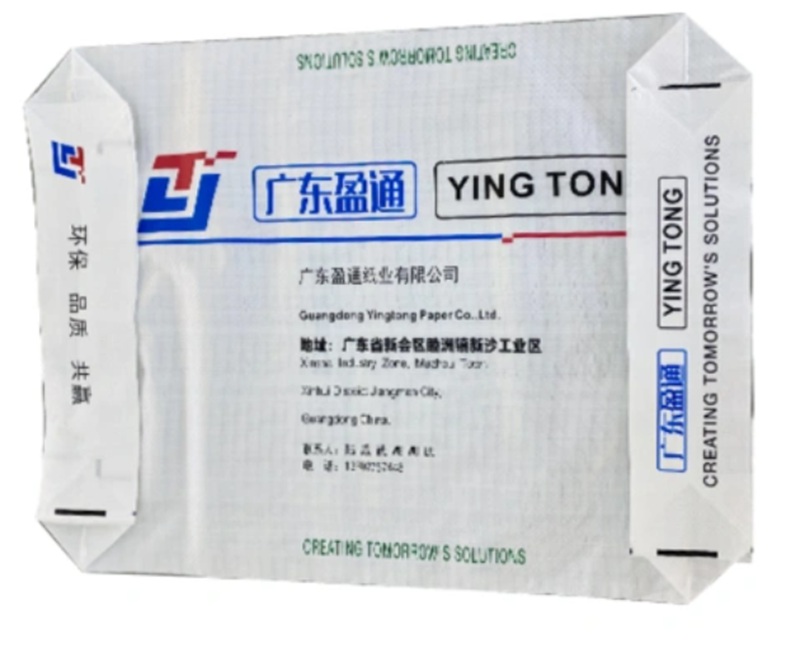

These are superior quality, square Custom Woven Bags that are designed for secure and efficient packaging solutions. These long lasting woven bags are perfect for keeping and moving of cement, fertilizers, grains and other bulk products. The upright standing of the bags helps in easy filling and stacking because they have a square bottom design which ensures stability.When carrying contents during transit, the valve pocket feature enables quick sealing thereby preventing spillage or any form of damage that may occur to it before reaching its destination. Requiring premium materials these can withstand wear and tear making them suitable for industrial or commercial use. Most appropriate for businesses looking adaptable tough and productive packages

Product color: 1-4 colors

Finished size: length 450-910, width 350-600, bottom width 80-180

Pattern customization: plastic woven bags can be customized according to customer requirements

Our main products include Kraft Paper valve bag, WPP Valve Bag, Kraft Paper Bag with Plastic Liner, cement woven bag, woven valve bag, kraft paper cement bag, etc.

Brand: OEM

Place Of Origin: China

Industry Application: Cement

Making Process: Composite Packaging Bag

Raw Materials: High Pressure Polyethylene Plastic Bag

Bag Variety: Upright Bag

Application: Chemical

Feature: Bio-Degradable

Material: PP

Shape: Square Bottom Bag

High Quality Material:

Custom Woven Polypropylene Bags are Made from premium woven materials, these bags offer excellent strength and durability, ensuring they can handle heavy loads without tearing or wearing out.

Square Bottom Design:

The square bottom allows the bags to stand upright, making them easy to fill, stack, and store, enhancing efficiency in handling and transportation.

Valve Pockets:

The valve pocket feature provides a quick and secure closure, minimizing spillage and ensuring the contents remain intact during transit.

Durability:

Designed to withstand rough handling and various environmental conditions, making them suitable for industrial and commercial use.

Versatility:

Extra Large Custom Woven Bag is Ideal for packaging a wide range of materials, including cement, fertilizers, grains, and other bulk products, offering flexible application options.

Customizable:

These bags can be customized to meet specific branding and size requirements, making them a versatile solution for different businesses.

Ease of Use:

The design facilitates easy filling and sealing, improving operational efficiency and reducing labor costs.

Eco-Friendly Option:

Made from recyclable materials, these woven bags offer an environmentally friendly packaging solution.

Cost-Effective:

Provides a reliable and durable packaging option that can reduce overall packaging costs due to their long-lasting nature and efficiency in use.

Enhanced Stability:

The robust construction and square bottom design ensure that the bags remain stable and upright, reducing the risk of spills and product loss.

Construction Industry:

Ideal for packaging and transporting bulk materials such as cement, sand, and gravel, ensuring secure and efficient handling.

Agriculture:

Perfect for storing and shipping fertilizers, seeds, and grains, offering a durable and reliable solution for agricultural products.

Food Industry:

Suitable for packaging bulk food items like flour, sugar, rice, and other grains, maintaining product integrity and preventing contamination.

The bags are made from high-quality woven materials, ensuring strength and durability for heavy-duty use.

The square bottom design allows the bags to stand upright, facilitating easy filling, stacking, and storage, which enhances efficiency in handling and transportation.

The valve pocket feature provides a quick and secure closure, minimizing spillage and ensuring that the contents remain intact during transit.

Yes, the bags can be customized to meet specific branding and size requirements, offering a versatile solution for different businesses.

These bags are ideal for packaging a wide range of materials, including cement, fertilizers, grains, bulk food items, chemicals, and more.

Yes, the bags are designed to withstand rough handling and various environmental conditions, making them suitable for industrial and commercial use.

Yes, the bags are made from recyclable materials, offering an environmentally friendly packaging solution.

Industries such as construction, agriculture, food, chemicals, retail, manufacturing, mining, pharmaceuticals, textiles, and recycling commonly use these bags.

WhatsApp:

WhatsApp: Phone:

Phone: Contact Now

Contact Now